Description

Perfect for startups or small scale production where flexibility is key.

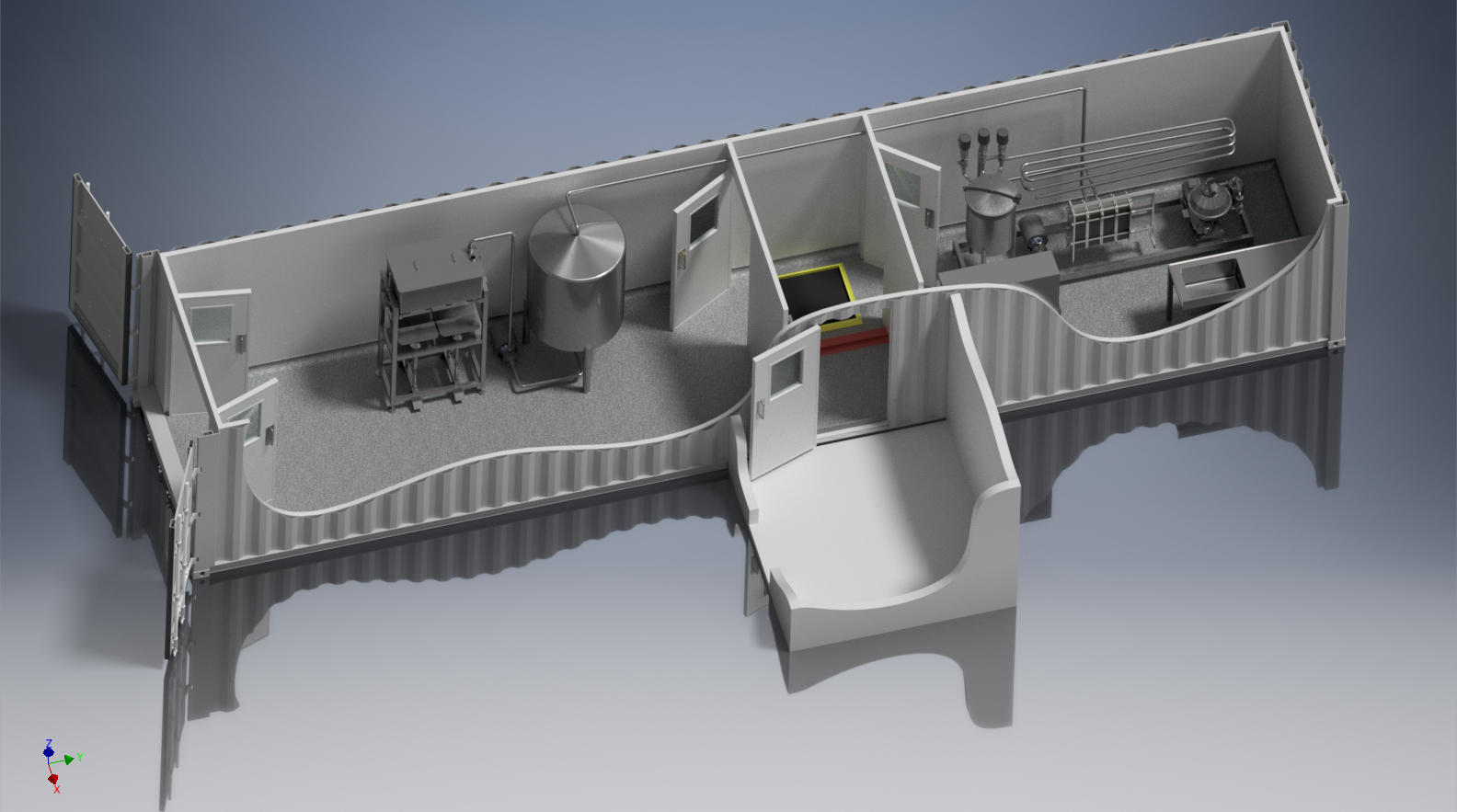

The beauty of a containerised process plant is that you receive a specifically designed, fit for purpose process plant that is housed in a fully hygienic, fitted out container that is built to meet the highest international food grade standards. Container plants are ideally suited to small scale and start-up plants where future production levels are unknown. Purchasing a container plant will help keep your costs down, while you begin production and therefore entry into your target market while allowing for future flexibility.

Technical Design: The majority of your process plant is designed and fabricated within either a 20 or 40 foot shipping container or a combination of these. Depending on your application, the only external elements of your plant will be the piping for water connection, boiler, chiller and raw product tank that may already be housed outside of the container.

Process Plant Fabrication & Workshop Commissioning: Our mechanical and electrical teams will fit out the container to meet the highest food grade standards. From there, the equipment and pipework will be fabricated and installed. Once the process plant fabrication has been completed, our team will commission the plant within our workshop. We will make sure everything is running the way that it should before we send it to the site.

Site Installation: Once both fabrication and commissioning is complete we will have the container transported to your location. When the container arrives our highly skilled engineers will come to your site and carry out all the work necessary to get you up and running.

Training: This is a very important aspect that needs a lot of consideration. Although many people that contact Thermaflo have experience working in a process plant before they purchase a container plant, there is still a lot to learn in the daily operations of the plant. Our team are able to teach all personnel involved in plant operations the correct way to operate the equipment. We will show you how to avoid waste, comply with industry standards and make your final product.

Compliance: Internationally there is very high compliance for the production of food, health care and pharmaceutical products. We will work closely with you to make sure that the products you are producing are safe for human consumption and that you are operating to the highest food safety standard. This will allow you to produce a safe, quality product, without worrying about product fault.

After Sales support: This includes both preventative maintenance service support on a scheduled programme as well as on the phone support for the operators and local tradesmen. For more information about how Thermaflo can assist you with developing a new processing plant within a hygienic shipping container go to our contact us page to leave a message or give us a call.