Cheese Process

Due to the many different types of cheese available, it is critical to understand your requirements and ideal outcomes.

We spend time making sure we understand your needs and expectations, then translate this into a technical design in cheese production.

| Products | Our systems have the ability to produce all types of cheese |

| Flow Rates | 150L Per Batch – 50,000L + Per Hour |

| Inlet Temperature | 4 Deg C – Any |

| Processing Temperature | 65 Deg C – 73 Deg C |

| Outlet Temperature | 25 Deg C – 35 Deg C |

Typical Process Steps

- Milk reception, pumping, cooling, standardisation and storage – Our solution will take into account volumes, temperatures and required milk standardisation.

- Heat Treatment – We will design the heat treatment plant to process and then cool the milk.

- Culture Addition – Adding bacterial cultures to the milk starts the fermentation process and lowers the pH to make it more acidic.

- Rennet Addition – This coagulates the milk creating curds, the building block of cheese.

- Cutting/Processing the Curd – The curd is cut and heated.

- Drain Whey – The whey is drained and can be stored for further processing.

- Hooping the Curd – The curd is put into moulds, and is later cut or pressed depending on the type of cheese.

- Dry Salt or Brine – Depending on the product, the curd is salted or placed in brine.

- Form cheese (if required) – The curd is placed into cheese blocks or moulds to form cheese.

- Store / Age (if required) – The cheese is stored until the desired age.

- Further Processing (if required) – The cheese can be sliced/grated etc prior to packaging.

- Package – We supply suitable packaging equipment specifically built to cater to your product requirements and production volumes.

Our Equipment

- Pasteurisers

- Cheese Vats

- Curd Distributors

- Cheese Press

- Cheese Brine Tank

- Electrical Control

Questions?

Our process team are here to help!

Please contact us on 06 777 5300 or through our contact form.

Cheese Installations / Upgrades Across Australia / NZ

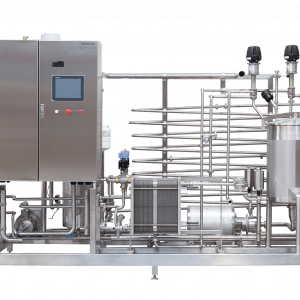

In early 2021, we commissioned Thermaflo to design and build a new cheese milk pasteuriser, suitable for cow, sheep, goat and deer milk.

Our brief to Thermaflo was for a HTST pasteuriser with a capacity of 2000L per hour, and we wanted a solution that came up to temperature faster, and was more energy efficient when compared with our existing unit.

We are happy with our new pasteuriser, it meets our criteria for capacity, speed and efficiency very well. Thermaflo’s solution also included an extra heat exchanger to heat potable water for our process, and for our CIP system.

We’ve noticed significant savings now that the new pasteuriser is in use. Our process is now considerably faster – we save around 2-3 hours each day, and our energy bill is half of what it used to be with the old unit. We are impressed with the results and Thermaflo’s engineering.

Type of Cheese

Fresh Cheese

- Mascarpone

- Cream Cheese

- Mozzarella

- Halloumi

- Ricotta

- Cottage Cheese

Soft-Ripened Cheese

- Brie

- Camembert

- Chevre

Semi-Soft Cheese

- Havarti

- Colby

- Paneer

Washed Rind Cheese

- Herve

- Munster

- Taleggio

- Limburger

Semi-Hard Cheese

- Edam

- Emmental

- Gouda

- Oaxaca

- Provolone

- Cheddar

- Gruyere

Hard Cheese

- Cheddar (Aged)

- Parmesan

- Pecorino

Blue Cheese

- Stilton

- Gorgonzola

- Roquefort

Our Partners:

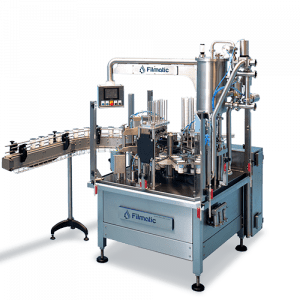

Within New Zealand and Australia, Thermaflo are proud to work with MilkyLAB and Christakis Agathangelou, both experts within their respective areas of expertise.

MilkyLAB are leaders in designing and producing machines and automatic systems to produce “Pasta Filata” Cheese such as Mozzarella, Pizza Cheese, Analogue Mozzarella, String cheese, as well as spread and processed cheese and Ricotta.

Based in Cyprus, Christakis are experts in the development and improvement of production lines for Halloumi, Feta, Yoghurt and Paneer.

-

Batch Pasteurisers

-

Cheese Vats

-

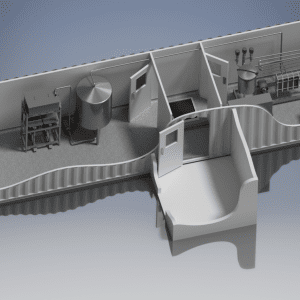

Containerised Process Plant

-

Filmatic Index Tub Fillers

-

Homogenisers

-

Inline Pasteurisers

-

Limitech MY Mix Lab Scale Mixer

-

Limitech P Series Mixers

-

MaxEverReady CIP System

-

MilkyLab Cheese Plants

-

Milkylab Pilot-Scale Cheese Systems

-

OnDemand Basic CIP System

-

Positive Displacement Pumps

-

Product Reception

-

Tanks & Vessels

-

Trepko Carousel Tub Filling Machines

-

Trepko Inline Aseptic Filling Machine

-

Trepko Rotary Tub Filling and Closing Machines

-

Trepko Semi-Automatic Tub Filling and Closing Machines