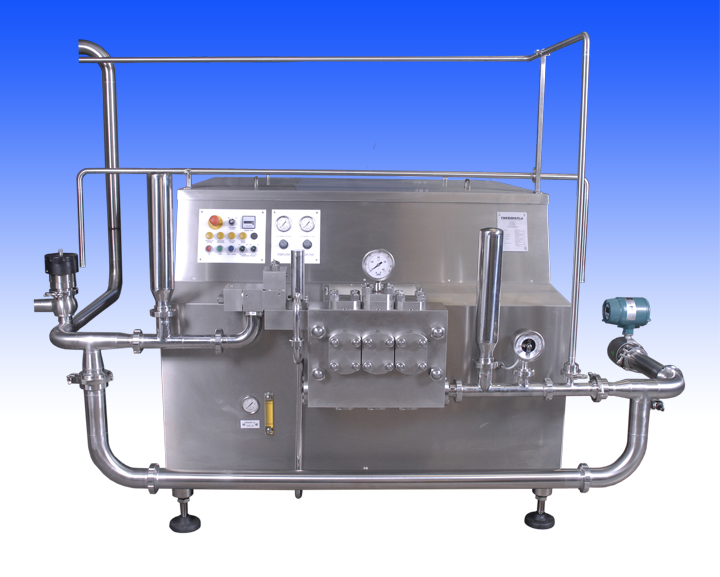

Description

Homogenisation is the process where the particle size in the product (measured in µm) is broken down and dispersed throughout

The most common application for homogenisation in dairy is to disperse the cream in milk or ice cream mix into a homogenous emulsion, preventing future cream separation and keeping the product in a consistent state over time.

Homogenisation occurs via mechanical means, the product is subjected to high pressure/velocity as it is forced through a small orifice causing turbulence and cavitation thus high shear breaking the particles down and dispersing them throughout.

Homogenisers are also used for various different pharmaceutical or laboratory applications. With a fully integrated design and process team at Thermaflo, we are able to specify the correct homogeniser and high-pressure pump units specifically for your application.