Description

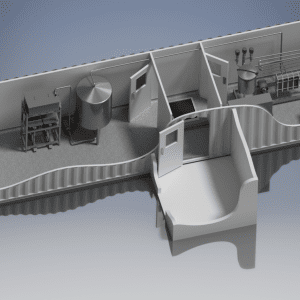

Our ice cream ingredient feeder is a durable and highly flexible machine that allows for flavour enhancing clusters to be uniformly and consistently added to a continual flow of ice cream without risk of blockages.

With a maximum ingredient dispensing capacity of 200kgs per hour from its 30-litre hopper, the RIF 1500 utilises a Lamella pumping system to ensure that it can easily handle a wide variety of products including chocolate, toffee, sweets, candy, fruit and jams. Furthermore, each is supplied with two feed augers which are machined to different pitches to ideally suit the size of the supplementary ingredient being added and guarantee a steady, controlled feed.

The RIF 1500 ice cream ingredient feeder is fully adjustable with three internal variable speed motors that independently control the auger, pump and blender, allowing manufacturers to easily and accurately manage the process from beginning to end.

Each ice cream ingredient feeder is constructed on a 100% stainless steel over-sized chassis to reduce vibrations and noise pollution and guarantee long-lasting reliability. The inner working parts are a unique blend of stainless and special alloys.

Why Choose a RIF 1500 Ice Cream Ingredient Feeder?

Well engineered and reliable: The internal mechanics, quality components and premier materials used in the construction of the RIF 1500 seamlessly combine to produce a machine that can be depended on day-in, day-out.

Simple to operate: Each RIF 1500 is fitted with an easy to use electrical control panel to provide complete yet simple control throughout the feeding process.

Easy to maintain: The durable and hygienic design of the RIF 1500 means that every component is easily accessible, ensuring maintenance is a simple and quick process.

Multiple feed augers: The RIF 1500 is supplied with two feed augers which are machined to different pitches to specifically suit the needs of differing sized products and maintain consistently high performance and a uniform feed.

Adaptable blender: The machine can easily handle a wide variety of products such as chocolate, toffee, sweets, candy, fruit and jams. The in-hopper agitator also keeps the particulate in the jams in suspension.

Fully adjustable: The machine is fully adjustable with three variable-speed motors that independently control the auger, pump and blender.