Case Study: Epicurean Dairy

Epicurean Dairy has been making gourmet yoghurt since 2009. Their brand ‘The Collective’ is in supermarkets across New Zealand and the UK.

Thermaflo has been working with Epicurean Dairy (and their predecessor) for almost 20 years, we’re proud to be working with them on their journey to make great-tasting yoghurt, that’s good for you, and good for the planet.

About Epicurean Dairy:

- ‘The Collective’ brand launched in 2009

- NZ’s best selling gourmet yoghurt within 10 months

- Entered into UK market in 2011

- UK Operation became a B Corp in 2020

- Dairy-free gourmet yoghurt launched 2021

- Target to become carbon neutral by 2025

Select Thermaflo Projects:

- Initial plant fabrication, install and commission

- HTST pasteuriser to process cheese and yoghurt milk alongside a blending plant upgrade

- A bespoke inline cooling process

- Additional incubation tanks

- Cream thermalisation

- New plant-based process project

- Fruit dosing

- Ongoing energy and water use consultancy work to ensure the yoghurt is manufactured as sustainably as possible.

- And numerous other projects

Products

- Dairy

- Yoghurt

- Fruit Dosing

- Cream

- Cheese

- Plant-based

- Yoghurt

- Fruit Dosing

Years Working Together

Major plant upgrades

Projects completed (and counting)

The Early Years – Canaan Cheese

Our first contact with the company that would become Epicurean Dairy, was in 2005.

The original owner Ilan, emailed us from Israel saying that he was coming to NZ and that he wanted to set up a dairy company called Canaan Cheese. He and his family subsequently arrived in New Zealand and engaged Thermaflo to build his boutique factory making Middle Eastern cheeses and yoghurts.

Ilan and his family grew the business over the next few years, winning multiple awards at the 2007 & 2008 Champion of Cheese Awards for their Mascarpone, Haloumi, Zefatit and Labane cheeses.

As the business continued to grow, Thermaflo was called on to design and build new plant to cope with the increased volumes.

New Owners, New Brand, New Products

Ilan and family sold the business to two chefs, Ofer and Angus, who had previous experience with developing great food recipes and turning these products into successful businesses, and Canaan Cheese became Epicurean Dairy.

The new owners set to work to develop a great tasting, gourmet yoghurt as well as a funky, memorable brand “The Collective” which was very well received by the market.

The product is a rich, thick and very smooth yoghurt with many variations of fruit not previously seen in the market. When the Thermaflo team first tried this, the immediate reaction was “Wow, this is really great yoghurt.”

Creative flavours such as Black Doris Plum and Blood Orange hit the supermarket shelves and quickly became a consumer favourite. In less than a year, The Collective was NZ’s best-selling gourmet yoghurt, and is sold internationally in the UK and Asia.

1st Upgrade – Multi-product Pasteuriser & Blending Plant Upgrade

This rapid surge in popularity brought with it production challenges for the factory to keep up with demand. The team at Epicurean tasked Thermaflo with designing and fabricating a new pasteuriser and upgrading the blending plant to:

- Meet the growing demand for yoghurt and

- Pasteurise cheese milk as well as yoghurt milk on the same machine

To keep up with the current and forecasted demand, the new pasteuriser needed to run at five times the flow rate of the previous pasteuriser!

All of this work was being carried out in a factory that was now running five days a week and with two shifts per day. The availability of shutdowns was very restricted, and the work that had to be carried out for this upgrade was very intrusive, as most of involved the Critical Hygiene Area of the factory.

Thermaflo and the Epicurean team worked closely together to very carefully plan out these; shutdowns, new equipment commissioning, and factory startups, to make sure that all areas were covered off.

2nd Upgrade – Bespoke Yoghurt Cooling Process

Demand for the Collective’s gourmet yoghurt continued to increase – much to the credit of the Epicurean team. The next bottleneck in the process was the time taken to cool the freshly made yoghurt. The team at Thermaflo designed, fabricated, and installed an inline cooling process to cool the final product for storage and filling.

With inline cooling of this type of product, there are significant challenges around product shearing – which destroys the product structure – so the challenge was to cool the yoghurt fast while still keeping its smooth texture and consistency.

Thermaflo developed the process and technology in-house to do just that and the result is that we can cool incubated yoghurt straight down to 10 deg C without any detrimental shearing, so it’s ready to store and fill.

This was a major step forward for the business, speeding up the cooling process allowed for more factory uptime, and therefore greater factory capacity.

3rd Upgrade – Additional Incubation Tanks

Despite the new larger capacity pasteuriser, and blending plant, demand kept growing, and production bottlenecks were again a concern.

The Epicurean and Thermaflo teams started work planning the next upgrade, this time adding in more capacity through an additional incubation tank.

The tank was designed by the Thermaflo process team, and the workshop team fabricated, installed and integrated it into the existing plant.

A 3rd Incubation tank would later be added to increase capacity.

4th Upgrade – Cream Thermalisation

The brief for this project was a heat treatment solution for cream to prolong shelf life – the cream is surplus to the yoghurt process, so Epicurean has repurposed it to a sour cream product.

This was a design and integration project, where the Thermalfo team designed and fabricated a bespoke piece of equipment to fit into a very tight space.

Raw milk would be pre-heated and pumped to a newly purchased cream separator, which would separate the raw milk into skim milk and cream.

The newly thermalised cream is cooled to 10 deg C, then pumped to storage until required.

The Thermaflo team designed, fabricated and installed the cream heat treatment (thermalisation), and the raw milk pre-heater, taking into account the specifications and capacity of the cream separator.

5th Upgrade – Standalone Plant-Based Process

Epicurean turned their attention to the growing demand for plant-based dairy alternatives and started work on developing a premium oat-based dairy-free yoghurt to complement their existing gourmet yoghurt range. Once trials were successfully completed, they engaged Thermaflo to scale up the process to commercial production levels.

At the time, oat milk was nowhere near its mainstream status and availability, so the Thermaflo team designed and built New Zealand’s first commercial oat milk plant.

Once the oat base is processed into oat milk, it goes through a fermentation process to turn it into a smooth and creamy gourmet yoghurt.

Given the nature of the product, our brief was to avoid any possibility of cross-contamination between the dairy and plant-based processes. This meant designing a standalone specialised yoghurt process with dedicated:

- Mixing, bending, fermentation and storage

- Heat treatment skid

- Cooling system

- CIP system

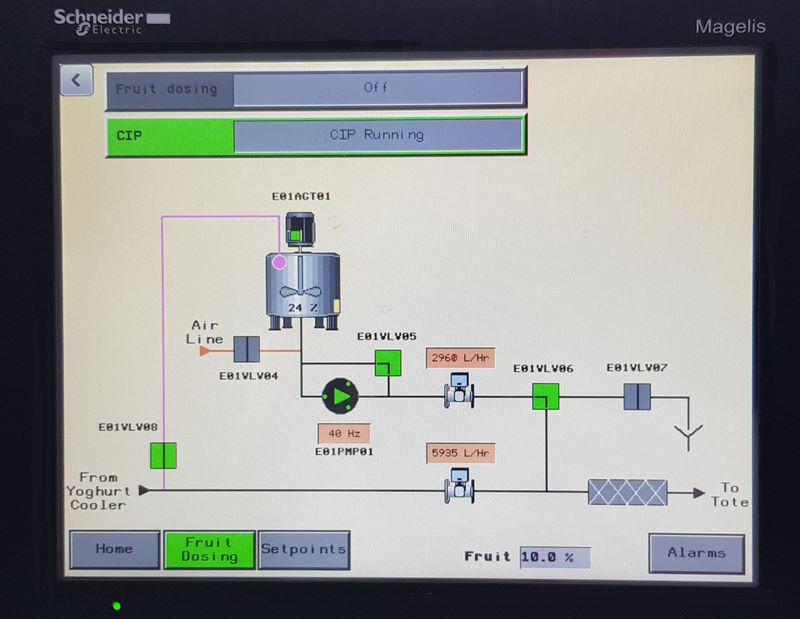

6th Upgrade – Fruit Dosing

Fruit is a high-value addition to yoghurt, so it’s vital to ensure accurate dosing and thorough mixing of the fruit into the yoghurt base.

Our brief for this project was:

- A mixing solution to create a homogeneous blend of yoghurt and fruit syrup.

- Mobility, so the skid could be easily pushed to and from the filling and CIP stations

- Automated, for dosing accuracy and ease of operation

7th Upgrade – Sustainability & Efficiency

Today, the team at Epicurean Dairy are still developing and releasing very creative products, with an eye towards sustainability, their latest is Splitz – packaged in recycled plastic – which is going gangbusters in the market.

We are also working with them on finding ways to reduce their water consumption and energy usage.

So far the Thermaflo investigation has identified:

- Water savings of 60,000L per week

- Which is also 60,000L less effluent going down the drain

- Natural gas energy savings of 2.2 megawatts per week

Estimated savings identified so far: 30 tonnes of CO2 emissions per year.

All of which help Epicurean Dairy meet their goal of becoming carbon neutral by 2025.

This is an ongoing project, with future upgrades and refinements planned.

We have been working with Thermaflo for nearly 20 years and they have designed and built our major upgrade work over this time, including our new plant-based process plant.

Over this time we have gotten to know their team very well, and would recommend their expertise to everyone.

– Angus Allan – Chief Creative Officer, Epicurean Dairy

Need A Quote Or Have Questions?

Send us an email and let us know your requirements and/or what you're wanting to achieve.

We'll take a look and come back to you ASAP.