Cream & Butter

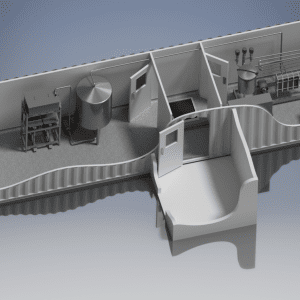

Cream requires careful plant design to correctly handle this high-value product to produce top quality cream.

Because cream is a delicate product, each stage of the process must be designed to ensure gentle handling. We’ve worked on many cream projects over the years and can help you with separation, cooling, storage, buffering or heat treatment.

| Products | Cream |

| Batch Size | 150L Per Batch – 10,000L Per Batch |

| Process Flow Rate | 150L Per Batch – 5,000L+ Per Hour |

Typical Process Steps

- Milk reception, pumping, cooling and storage – Our solution will take into account daily volumes, incoming milk temperature and required milk storage.

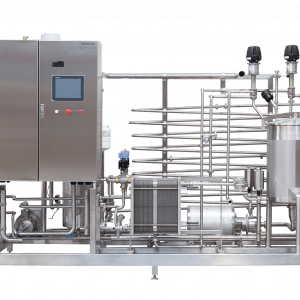

- Milk Pasteurisation – We will design the heat treatment plant to process the raw milk.

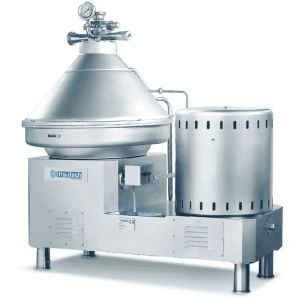

- Separation & standardisation – The most important part of the cream process is a gentle separation of the cream from the milk. We can also offer fat standardisation.

- Cream Pasteurisation – We will design the heat treatment plant to process the cream to meet your required shelf life.

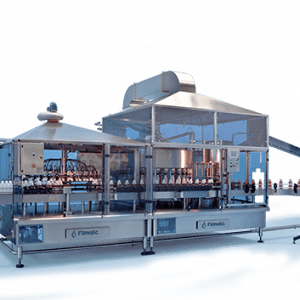

- Cooling – Once pasteurised the cream is cooled and ready for packaging or further processing.

- Culturing or Souring (for cultured cream, butter or cheeses) – If required for the process.

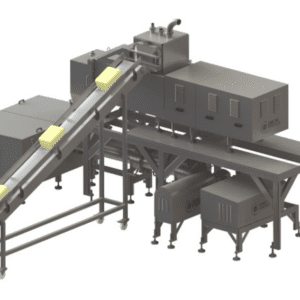

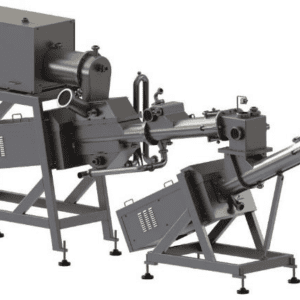

- Churning (for butter) – Either as a batch or continuous process.

Once treated, the cream can be packaged or processed further into products such as:

- Butter

- AMF (Anhydrous Milk Fat)

- Whipping or pouring cream

- Cultured cream

- Various cream cheeses

With our extensive knowledge of the cream production process, we will work with you to develop a system that delivers your product requirements.

Questions?

Our process team are here to help!

Please contact us on 06 777 5300 or through our contact form.