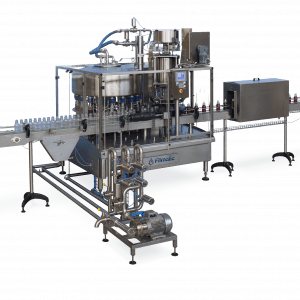

Description

Cream separation, either from milk or whey, is a key process in dairy processing.

Gentle treatment of the milk to avoid damaging the fat globules is an essential requirement that Frautech Separators can guarantee thanks to the optimized design in feeding the separator. Under optimal feeding and process conditions, the residual fat in skimmed milk is always at the lowest possible level, i.e. 0.05% or less.

Milk fat standardization with Frautech cream separators can be achieved with the built-in standardizing apparatus that allows fat re-mixing into the skimmed milk for manual adjustment.

How the Frautech Cream Separator Works:

- Whole milk or whey is fed under pressure to the separator.

- It then flows smoothly into the bowl through the feed pipe and the distributor and starts rising through the rising channels.

- Due to the centrifugal force and the milk’s higher specific weight, it is forced towards the periphery of the bowl while the cream is concentrated in the central area.

- Both skimmed milk and cream rise along their respective paths and are pumped out or leave the separator, respectively, through enclosed pipes.

- Solids are also subjected to the action of the centrifugal force and are pushed to the periphery of the bowl, accumulating in the area that holds the solids, and automatically discharged at preset intervals.