Ice Cream

To produce a high-quality ice cream mix, it’s vitally important that the mix process is designed correctly to make a gourmet product.

Ice cream manufacturing all starts with the design to achieve that perfect, velvet mouthfeel. We make sure that we understand what you are wanting, then translate this into the technical design.

We have a wealth of experience with ice cream mix plant design and fabrication, with many of our clients winning top awards for their product. Whether you require a boutique batch process, or a larger scale inline ice cream mix plant, we will design the process to your requirements.

| Products | Ice Cream, Gelato, Frozen Yoghurt |

| Ice Cream Mix Preparation | 100L Per Batch – 10,000L Per Hour |

| Pasteurising Inlet Temperature | 4 Deg C – Any |

| Pasteurising Temperature | 85 Deg C – 90 Deg C |

| Pasteurising Outlet Temperature | Any – 4 Deg C For Ice Cream Mix |

| Churn inlet temperature | 4 degrees – 10 degrees |

| Churn outlet temperature | -4 Degrees – -20 Degrees |

| Churn Flow Rate | 100L Per Hour – 1,500L Per hour |

Typical Process Steps:

- Ingredient Mixing: Depending on what ingredients you are putting into your mix, the amount of sugar, gums, additional cream, all affect the pasteurisation, homogenisation and storage processes. We pay particular attention to the mixing stage to ensure full hydration of the various components. Typically this would involve inline or in-tank high-shear mixing depending on your requirement.

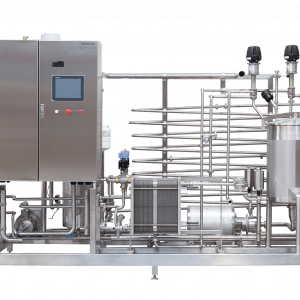

- Pasteurisation: The ice-cream mix is then forwarded to either a batch pasteuriser or continuous HTST pasteuriser for the heat treatment process. The mix is pasteurised to dissolve ingredients and destroy bacteria.

- Homogenisation: Homogenisation breaks up and distributes the fat/oil content through the mix which improves the texture.

- Ageing: Following on from the pasteurisation, homogenisation and cooling of your ice cream mix, it is then stored in an aging tank where it is kept at 4 deg C or less, giving the fat time to partially crystallize, and the protein stabilizers time to hydrate. We are able to build custom tanks that are designed specifically for your process and plant layout to best utilise the space that is available.

- Freezing: We have a great range of ice cream churns available, these are state of the art, specifically designed to enhance the finished product.

- Bulky Ingredient Dosing (if required): we can supply a solution that will dose and dynamically mix fruit/swirls/confectionary/nuts into ice cream in a continuous process or a static mixing solution.

- Filling: We have a range of ice cream fillers to provide you with a complete process line.

We offer a complete range of ice cream mix preparation equipment, from small boutique processes all the way through to large commercial scale equipment. It is this flexibility that ensures you get a mix plant that is fit for purpose, will allow you to produce a top-quality product and will assist your company as it continues to grow while production levels increase.

-

Ageing Tanks

-

Batch Pasteurisers

-

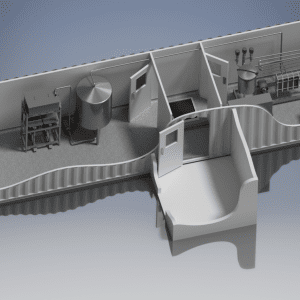

Containerised Process Plant

-

Fruit Dosing Machines

-

Homogenisers

-

Ice Cream Churns

-

Ice Cream Ingredient Feeders

-

Ice Cream Mix Plant

-

Ice Cream Ripple Pumps

-

Ingredient Blending, Mixing & Dosing

-

Inline Pasteurisers

-

Linear Ice Cream Cup Tub & Cone Filler

-

Positive Displacement Pumps

-

Rotary Ice Cream Filler

-

Semi-Automatic Ice Cream Filler

-

Tanks & Vessels

Questions?

Our process team are here to help!

Please contact us on 06 777 5300 or through our contact form.