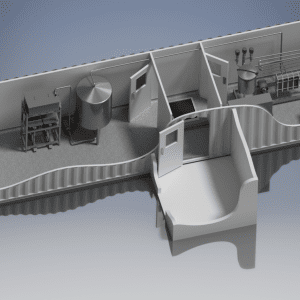

Description

Pilot-scale cheese system with an all-in-one stretching/moulding machine for small-scale production suitable for R&D laboratories

Both systems are suitable for processing fresh and industrial blocks of curd, buffalo curd, powders, rennet casein, starch and vegetable or animal fat

- Built in AISI 304 stainless steel, double wall vat for the steam injection into the jacket

- Steam is provided by an electric steam generator for the stretching phase

- Product stretching is performed by

- Steam injection

- Direct into product or

- Via the double jacket

- The stretching vat is equipped with two bi-directional augers, with adjustable speed

- Thermoregulator with digital display for temperature control

- The moulding vat is equipped by two augers and one moulding roller

- The moulding roller and the augers have adjustable speed

- Includes HMI to control the different stretching – moulding process phases

Moulding Rollers Available:

- Mozzarella in balls: from 1 to 200g

- Scamorza up to 300g

- Cylindrical or rectangular block up to 1000g

- String cheese/spaghetti cheese

- Conveyor for continuous cords and nodini