Description

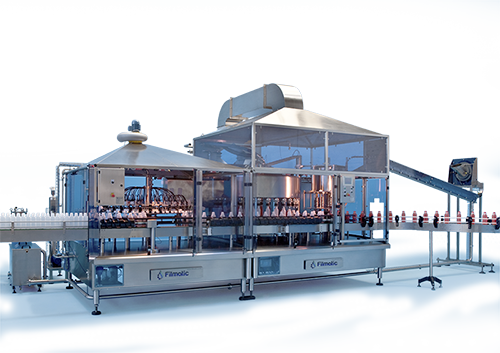

Filmatic ESL Bottle Filling Machines (Extended Shelf Life) is expanding the lifespan of perishable products through packaging, without changing the taste characteristics of the freshly produced product itself.

The continuous variable flow control valve promoted non-contact, non-drop filling creating a hygienic filling environment while also minimising foaming issues. All product contact components are thoroughly cleaned by the closed-loop automated CIP system.

ESL is a great choice for those with high-value products wanting a longer shelf life, without the additional expense of aseptic technology. ESL is well suited for products such as Milk, Cream & Juice etc.

Factors to consider for ESL:

Air Management

- Clean room = Class 100

- Pre-filtration

- HEPA filtration

- Diffuser

- Laminar vertical airflow

Cap Sterilization

Eliminate potential contamination issues from the cap.

Container Sterilization

Single or double stage rinsing using a combination of sanitizing agents available.

Auto-sanitise and CIP

- Auto-sanitise (Surface Sterilization)

- A multi-stage programmable system to conform to individual product requirements.

- CIP (Clean in Place)

- Multi-stage, two-directional systems which can be programmed to conform to individual product requirements.