Description

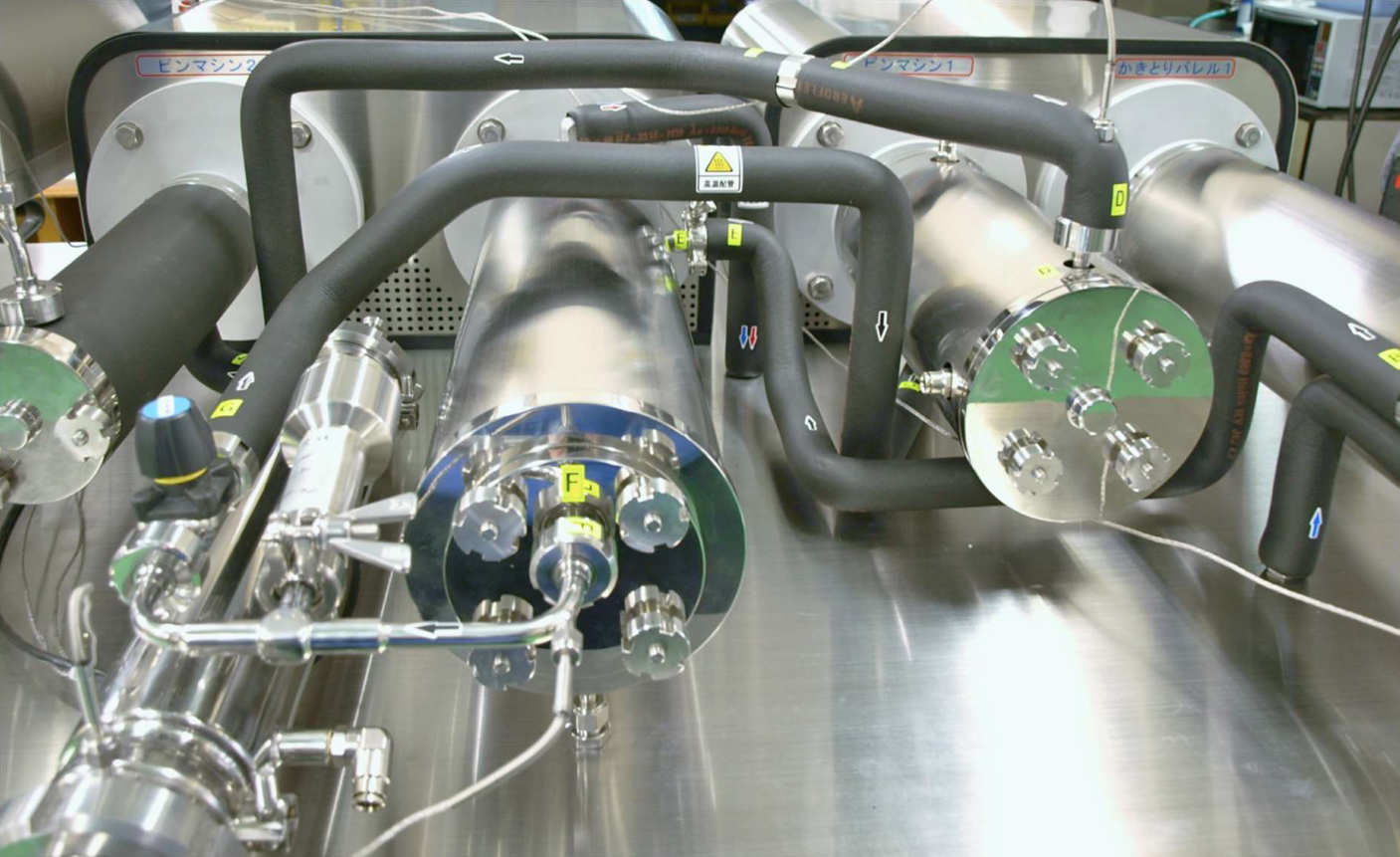

A continuous Margarine & Spreads Processor designed to replicate industrial scale units on a laboratory/pilot scale. Initial formulation, recipe development and screening are easily carried out.

All machines are designed to replicate full-scale production machines on a pilot scale. The design incorporates different pump options to suit the product to be processed. All product contact surfaces are of FDA approved materials. Each system has built-in CIP, so there is no need to add external feed tanks and pumps.

- Minimum sample required.

- Jacketed feed hopper for control of product inlet temperature.

- Hard chrome plated barrels.

- Single barrel + pinworker or twin barrel + pinworker.

- Shaft speeds to 1500 rpm.

- Speed and torque indicators.

- Can be used for sheet margarines with resting tubes of any time.

- Built in refrigerator or your chilled water supply.

- Built in true CIP (Clean In Place), flow for CIP more than 500 Ltr per hour.

- Electrically heated hot water recirculator as option for CIP heating.

- No steam required.

- Level sensor in hopper for easy wash out after product and CIP.

- Computer interface with real time temperature recording.