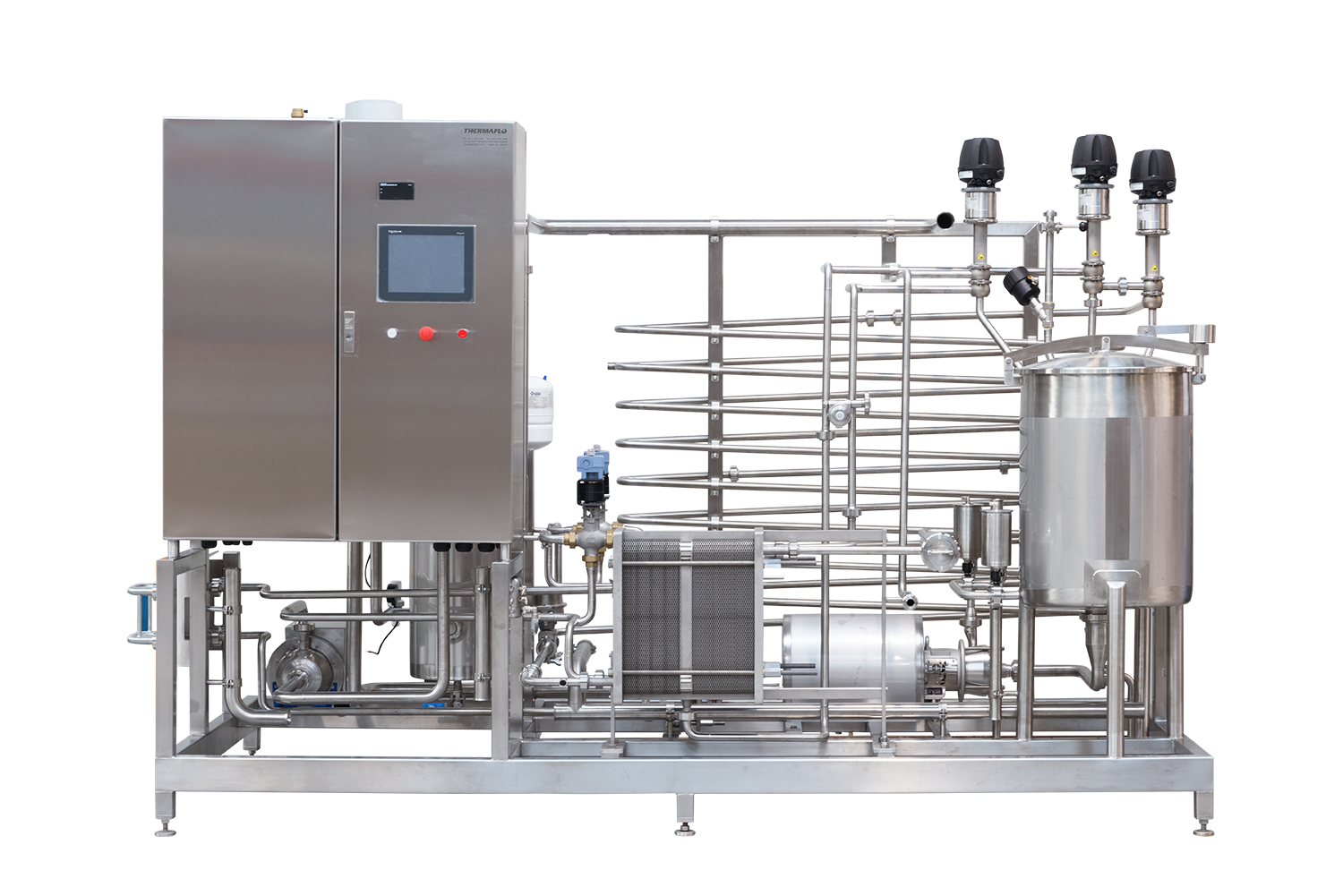

Description

Pasteurisation is the process of heat treating a product to ensure that it is safe for human consumption and to increase the shelf life of the product. Depending on the product you are pasteurising and what the intended end product is, each pasteurisation process requires its own specific design. We supply top quality, efficient pasteurisers that are specifically designed to produce repeatable results that meet your process needs. Our inline pasteurisers systems range from 1000L per hour to 50,000+ L per hour and can be custom designed for volumes within this range. If you are processing smaller volumes, see our batch pasteurisers here.

Products:

- All Dairy products,

- Plant-based milk alternatives (Coconut, Almond, Oat, Soy etc),

- Juice (vegetable & fruit),

- Edible Oils,

- Honey,

- Soups & Condiments,

- Egg Pulp,

- Syrups,

- Other