Plant Based Yoghurts

- Home

- /

- Process Solutions

- /

- Plant Based Dairy Alternatives

- /

- Plant Based Yoghurts

Plant-based yoghurt is a category growing in leaps and bounds.

Even though the end product is similar in appearance and mouthfeel, plant-based products do come with processing challenges you don’t find in dairy processing, and the fermentation process adds extra complexity on top.

Case Study: Epicurean Dairy

We’ve worked with the team at Epicurean Dairy / The Collective for nearly 20 years, across dozens of projects – large and small.

Click here to read about some of the projects we’ve completed for Epicurean Dairy

| Products | Oat, soy, rice, coconut, almonds, hemp, pea, or a combination of ingredients. |

| Flow Rates | 150L Per Batch – 20,000L + Per Hour |

Typical Process Steps

- Dry mill / Wet mill: Your raw ingredients are incorporated into a slurry via a dry mill / wet mill process.

- Enzyme and Heat treatment (if required): With a product like oats, an enzyme treatment is needed to reduce viscosity and, break down the starch into sugars for natural sweetness. The enzyme must then be deactivated via heat treatment. Taking the type of product to be produced into account, we design the heat treatment specifically to achieve the correct temperature and holding time to suit your product.

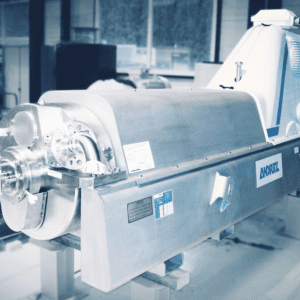

- Separation: A decanter centrifuge is needed to process the slurry to remove insoluble fibre and larger particulates to make your yoghurt mix match your recipe.

- Formulation: Additional components/flavours/stabilisers can be mixed. This will likely include vitamins and minerals (such as calcium) to increase the nutritional value, and will include some form of oil to add fat content. The addition of oil is needed to give the ‘creamy’ mouthfeel you find in dairy products.

- Heat Treatment: Just as you’d find in dairy products, the plant milk undergoes pasteurisation or UHT to extend shelf life.

- Culture addition, fermentation and cooling: The plant milk begins the process to become yoghurt. Whether you are fermenting in tank or in the final product tub, our design will allow the perfect product to be made. We also have a great system for inline cooling for stirred yoghurt that doesn’t affect the final curd structure.

- Fruit Dosing (if required): we can supply a solution that will dose and dynamically mix fruit into yoghurt in a continuous process or a static mixing solution.

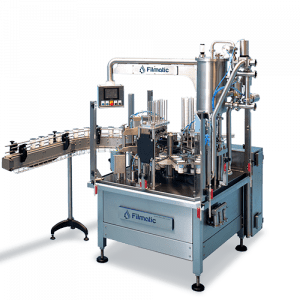

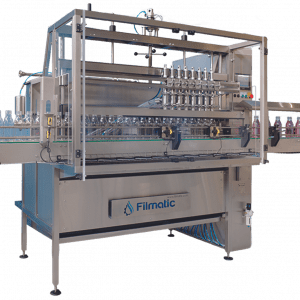

- Filling/packaging: Depending on your product, we supply a wide range of fillers/packaging machines specifically built to cater to your product requirements. Options range from entry-level fillers, right through to fully automatic machines capable of high-volume throughput.

-

Batch Pasteurisers

-

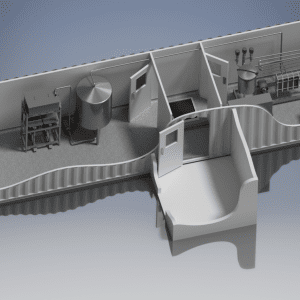

Containerised Process Plant

-

Filmatic Index Tub Fillers

-

Filmatic Inline Piston/Pump Filler

-

Fruit Dosing Machines

-

Homogenisers

-

Incubation Tanks

-

Ingredient Blending, Mixing & Dosing

-

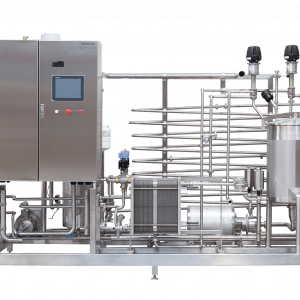

Inline Pasteurisers

-

Limitech MY Mix Lab Scale Mixer

-

Margarine & Spreads Processor

-

MaxEverReady CIP System

-

Positive Displacement Pumps

-

Product Reception

-

Tanks & Vessels

-

Trepko Carousel Tub Filling Machines

-

Trepko Inline Aseptic Filling Machine

-

Trepko Inline Form Fill Sealing Machine

-

Trepko Rotary Tub Filling and Closing Machines

-

Trepko Semi-Automatic Tub Filling and Closing Machines

Questions?

Our process team are here to help!

Please contact us on 06 777 5300 or through our contact form.