Ice Cream Production

We have considerable experience in ice cream/gelato/frozen yogurt processes across Australasia.

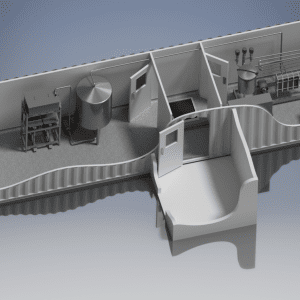

We have worked on many projects, from equipment and/or capacity upgrades, right through to the design, fabrication, and installation of complete plants.

| Products | Ice Cream, Gelato, Frozen Yoghurt |

| Ice Cream Mix Preparation | 100L Per Batch – 10,000L Per Hour |

| Pasteurising Inlet Temperature | 4 Deg C – 8 Deg C |

| Pasteurising Temperature | 73 Deg C – 93 Deg C |

| Pasteurising Outlet Temperature | < 4 Deg C For Ice Cream Mix |

| Churn inlet temperature | 4 degrees – 8 degrees |

| Churn outlet temperature | < 4 Degrees |

| Churn Flow Rate | 100L Per Hour – 1,500L Per hour |

How we can help:

- Technical Design – Ice cream manufacturing all starts with the design to achieve that perfect, velvet mouthfeel. We make sure that we understand what the client is wanting, then translate this into the technical design.

- Ice-Cream / Gelato Ingredient Mixing – Due to the wide variety of ingredients that could be used, we pay particular attention to the mixing stage to ensure full hydration of the various components. Typically this would involve inline or in-tank high-shear mixing depending on your requirement.

- Heat Treatment – The ice-cream mix is then forwarded to either a batch pasteuriser or continuous HTST pasteuriser for the heat treatment process.

- Homogenisation – Again, depending on the specifications, a homogeniser can be included to ensure that the final mix is at the correct micron level.

- Ice-Cream Aging Tanks – Once the mix has been heat treated and cooled, it is then stored in an aging tank where it is kept at 4 deg C or less, giving the milk fat time to partially crystallize, and the protein stabilizers time to hydrate.

- Ice-Cream Churn – We have a great range of ice cream churns available, these are state of the art, specifically designed to enhance the finished product.

- Ice-Cream Fillers – We will supply the correct filler solution: this will depend on the type and packed weight of packaging and the required flow rate.

Questions?

Our process team are here to help!

Please contact us on 06 777 5300 or through our contact form.