Description

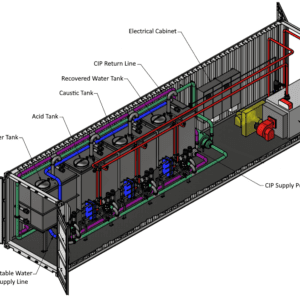

The MaxEverReady CIP System is a standard two tank, fully automated, high/constant demand CIP solution. This system is ready at all times, and is always at temperature. The system is well suited for multiple circuits with unscheduled cycles.

Extra tanks can be added for Rinse Recovery and or potable stored water supply as an option. Ask us for further information.

*Image shown includes a MaxEverReady CIP Kitchen with an additional tank option (3 tanks total).