Description

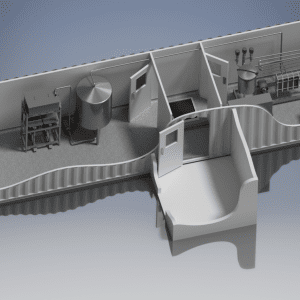

The Direct Steam Injection UHT/HTST system is designed for comparisons of heat treatment with either direct heating or indirect heating.

The machine can be supplied with tubes, plates or both. Processing using either direct heating or indirect heating at temperatures to 152 deg C and flow rates from 10 to 40 Ltr per hour. Easy changeover from direct heating or indirect heating by the touch of a button. Just select which system is to be used from the touch panel menu and the machine is ready to use.

Individual tubes are utilized to give a wide variety of heating and cooling duties. The tubes are manufactured to our own specification and are profiled to give turbulence at the low flow rates to enable scale up to production.

No-bond Gasketed plate heat exchangers offer a wide variety of heating and cooling duties. The plates are manufactured to our own specification and can be supplied as 1 complete plate pack or individual units for easy maintenance.

Each section is individually controlled and the flow path of the system is shown on the touch panel

- Minimum sample required.

- Holding tubes of any time available and can be placed wherever needed.

- Built in refrigerator or your chilled water supply.

- Touch panel control fascia with flow path of system.

- Vacuum pump to 400 mbar.

- PID controlled steam valve.

- Aseptic sampling when used with the optional Clean Bench.

- Level sensor in hopper for easy wash out after product and CIP.

- Steam, mains water and a suitable drain required.

- Compressed air at 6 bar for the divert valves.