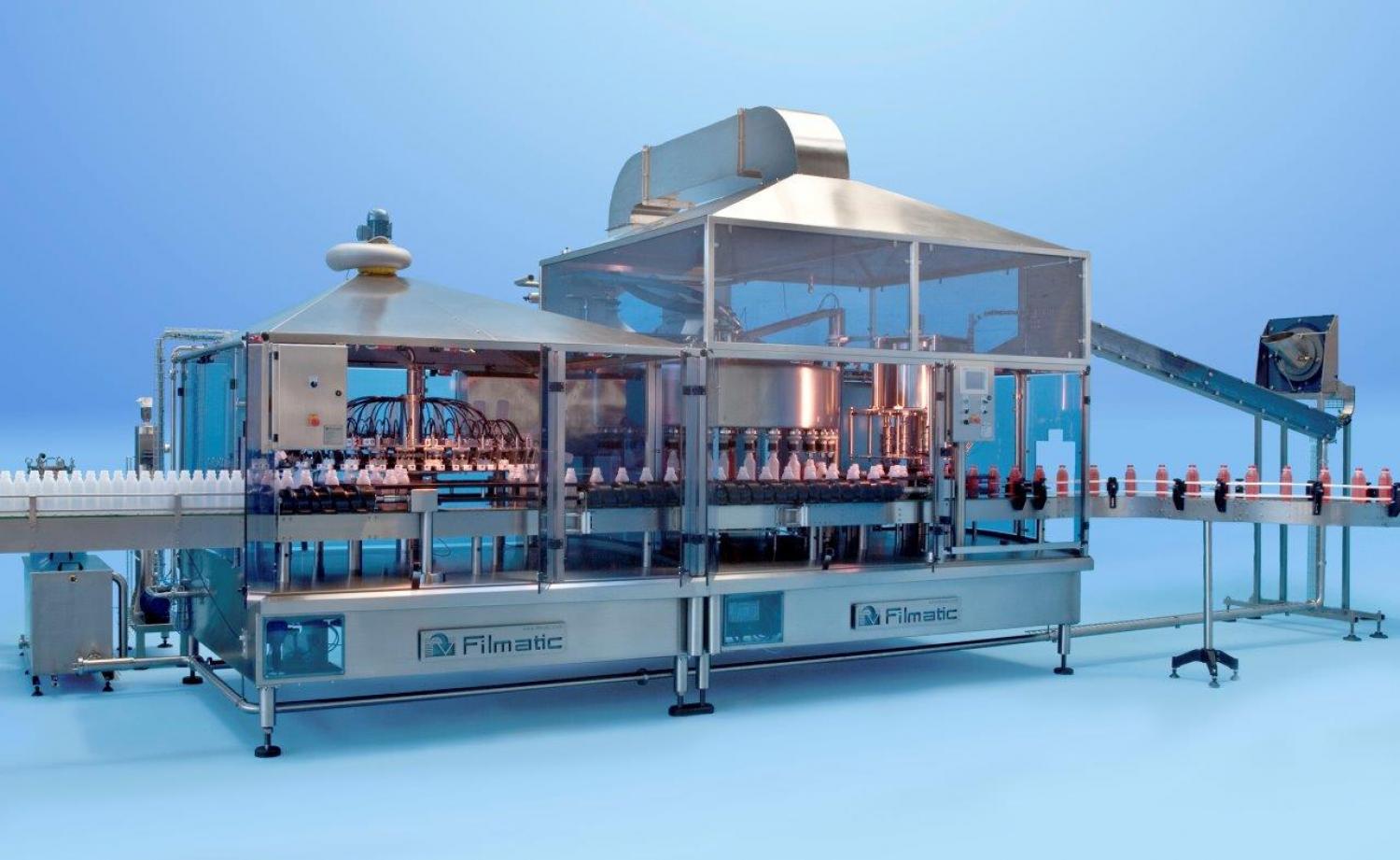

Aseptic / Hygienic Filling

- Home

- /

- Process Equipment

- /

- Filling Machines

- /

- Aseptic / Hygienic Filling

Tell us the desired shelf life for your product, and we’ll work with you on the front end process, as well as a suitable filler to ensure the ideal outcome.

Depending on your final product, we have a range of ESL / Aseptic / hygienic filling options to assist in extending the shelf life of your products.

What we look at to help extend the shelf life of your product:

Air Management

- Cleanroom = Class 100

- Pre-filtration

- HEPA filtration

- Diffuser

- Laminar vertical airflow

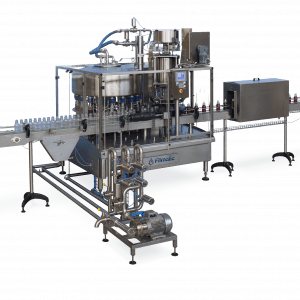

Cap Sterilization

- Eliminate potential contamination issues for the cap.

Container Sterilization

- Single or double stage rinsing using a combination of sanitizing agents available.

Auto-sanitise and CIP

- Auto-sanitise (Surface Sterilization)

- A multi-stage programmable system to conform to individual product requirements.

- CIP (Clean in Place)

- A multi-stage, two-directional systems which can be programmed to conform to individual product requirements.

Take a look at the filling machine options below for more information and specifications.

Questions?

Our filling & packaging team are here to help!

Please contact us at 06 777 5300 or through our contact form.