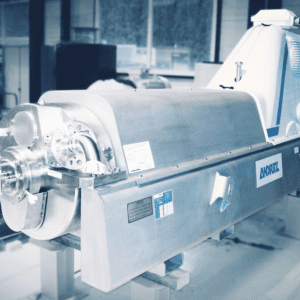

Description

A milk separator (also called a clarifier) is a very important step in milk processing when aiming for high-quality dairy products. The purpose of milk clarification is to improve the milk quality by removing solid impurities such as dirt particles, somatic cells, and bacteria.

How the Frautech Milk Separator Works:

- The milk/whey is fed under pressure through an enclosed pipe.

- It then flows smoothly into the bowl through the feed pipe and the distributor.

- With the action of the centrifugal force, the solids are forced towards the periphery of the bowl and accumulate in the solids acceleration zone.

- The clarified milk/whey rises through the disc stack up to the centripetal pump that discharges it through an enclosed pipe.

- Accumulated solids are automatically discharged at pre-set intervals.