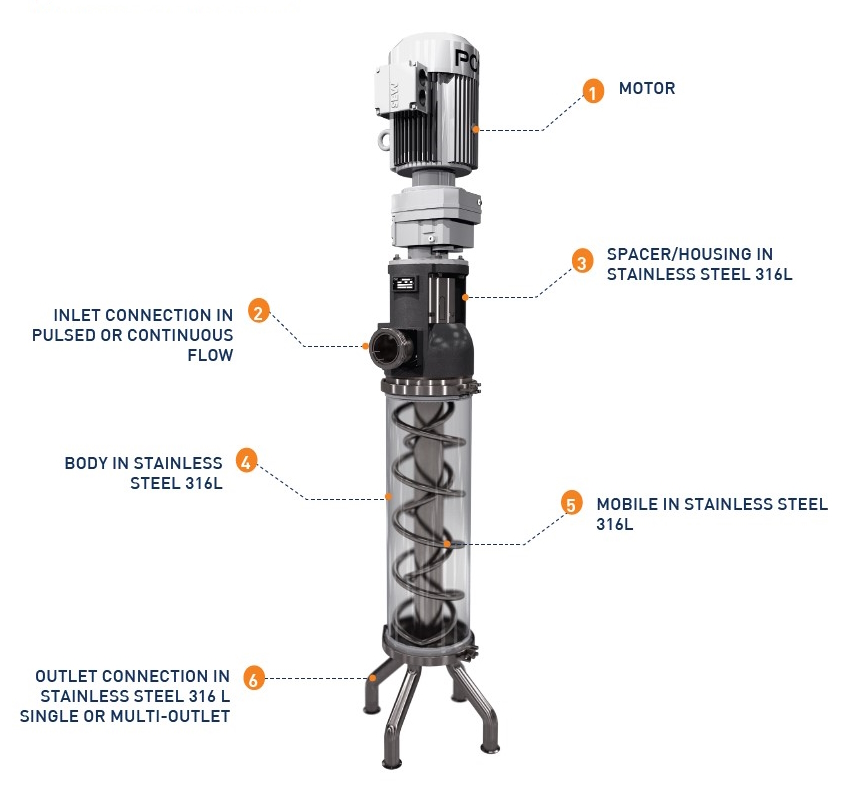

Description

The Dosymix inline mixer accurately distributes and preserves the valuable ingredients in your production line. Designed for just in time mixing prior to filling.

Twin helixes are welded to an impeller in opposite directions to create the gentle upwards and downwards flow – this body design ensures gentle mixing to preserve the structure of the ingredients.