Description

The Trepko 760 series Pick & Place System is a fully automatic unit, suitable for top loading of products into cases, trays or crates. Products that can be lifted with vacuum, magnetic tool or gripper can also be packed.

The machine consists of tooth belt driven linear units for X and Z movements mounted in a stainless steel frame with interlocked guarding. Products and package conveyors with guides included.

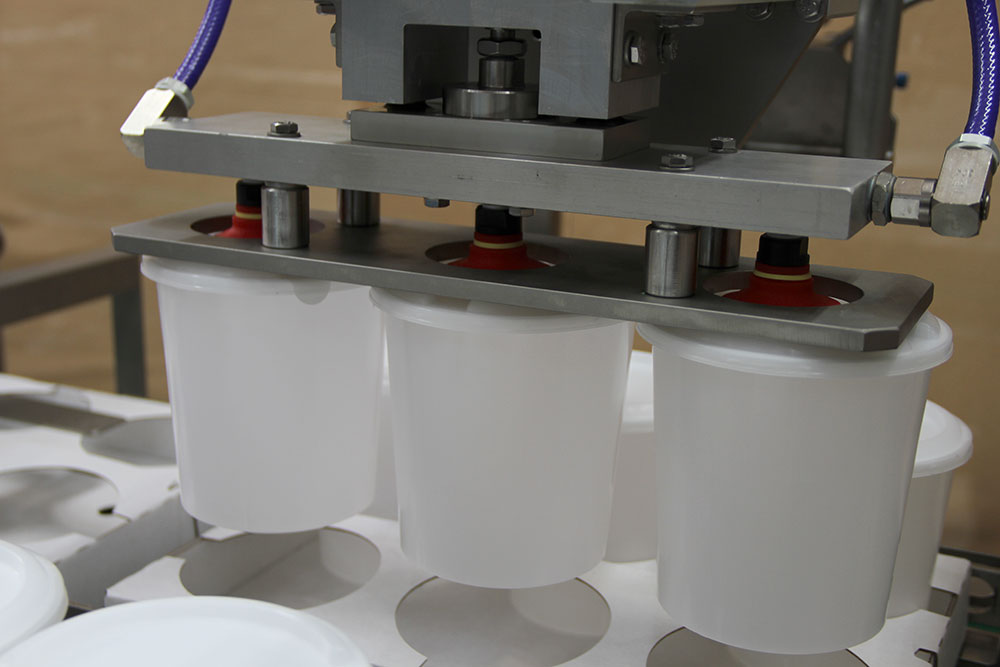

The boxes arrive into the Pick and Place Unit from an infeed box conveyor with the short side leading. They come two trays at a time to a collating point. The products arrive in a single conveyor and are queued until there is the desired amount of containers. The lifting tool, assisted by suction cups, lifts and places the containers into the boxes. The Pick and Place Machine repeats this action until we have the desired pack pattern on two layers.

The system facilitates the packing of fragile products since the packing pattern does not primarily need to be used as a support. Gentle handling is enabled as the unit works according to the principle of controlled acceleration/deceleration. The drive unit is equipped with a safety clutch connected to the alarm lamp.

The entire packing procedure takes place in full view on one level, which makes the equipment easily accessible for format changes and maintenance, etc.

The ready box is fed out on a single lane conveyor.