Description

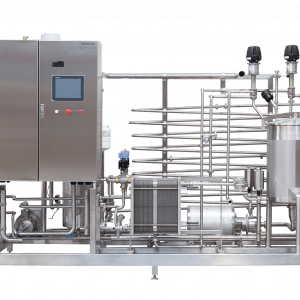

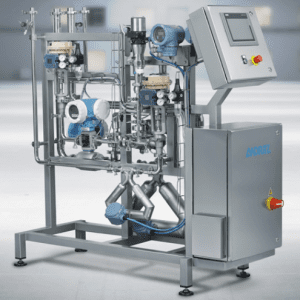

ArtBREW, the craft beer clarifier from Frautech, is a high-quality simple-to-operate, plug-and-play beer clarification solution for your brewery. Combining efficiency and ease of maintenance, ArtBREW is the right ingredient for your success in the craft brewing industry.

Why use a clarifier for your brewery?

- Reduced Oxygen Pickup – The KO₂ system reduces oxygen pick-up.

- Higher yields per tank – Up to 10% higher yields compared to traditional filtration and settling methods.

- Faster Tank Turnaround – Reduced processing times when compared to traditional filtration and settling methods.

- Spend Less On Consumables – The consumption of filter aids is minimized or eliminated, and your filter shelf life is extended.

- Low total cost of ownership – you’ll save energy with the variable speed belt drive, and the low cost of spare parts and ease of maintenance.

- Very short return on investment – Typically less than 24 months.