Cheese Production

Due to the many different types of cheese available, it is critical to understand client requirements.

We spend time making sure we understand your needs and expectations, then translate this into a technical design in cheese production.

| Products | Our systems have the ability to produce all types of cheese |

| Make Volumes | 150L – 10,000L Per Vat |

| Inlet Temperature | 4 Deg C – Any |

| Cheesemaking Temperature |

25 Deg C – 35 Deg C + Additional cooking temperature (if required) |

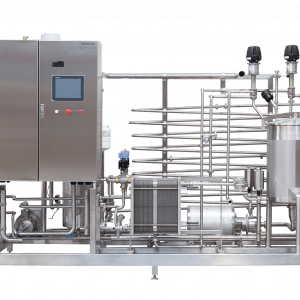

Cheese Milk Pasteurisers – We design and manufacture both HTST and Batch pasteurisers to suit your daily cheese milk volumes.

Cheese Vats – We design and manufacture a whole range of cheese vats to suit any volume and purpose. Whether you require round or rectangular with oval end, heated and insulated, overhead stirring and curd-cutting, taking the type of cheese that you wish to produce into account, we will consult with our cheese-making clients and design the most suitable cheese vats for you.

Curd Distributors, Cheese Moulds, Draining Trays, Draining Tables, Cheese Working Tables – Depending on your individual requirements we can include any equipment for the cheese-making process.

Cheese Press – Again we take into account your requirement, e.g. the mould sizes and quantity so that we can supply a suitable press.

Cheese Brine Tank – Designed and manufactured by Thermaflo to suit the site requirements.

Electrical Control – We design and build the central control for the above plant: by doing this we take responsibility for the interface of the plant and this enables us to deliver the complete integrated solution.

-

Batch Pasteurisers

-

Cheese Vats

-

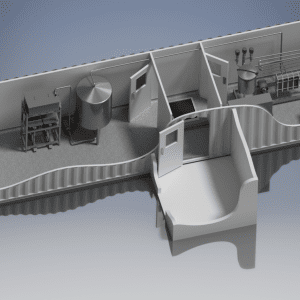

Containerised Process Plant

-

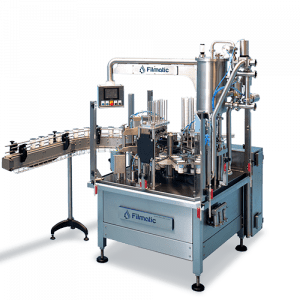

Filmatic Index Tub Fillers

-

Homogenisers

-

Inline Pasteurisers

-

Limitech MY Mix Lab Scale Mixer

-

Limitech P Series Mixers

-

MaxEverReady CIP System

-

MilkyLab Cheese Plants

-

Milkylab Pilot-Scale Cheese Systems

-

OnDemand Basic CIP System

-

Positive Displacement Pumps

-

Product Reception

-

Tanks & Vessels

-

Trepko Carousel Tub Filling Machines

-

Trepko Inline Aseptic Filling Machine

-

Trepko Rotary Tub Filling and Closing Machines

-

Trepko Semi-Automatic Tub Filling and Closing Machines

Questions?

Our process team are here to help!

Please contact us on 06 777 5300 or through our contact form.

“We purchased a 5,000L per hour fresh milk process line from Thermaflo to help us increase our production. After two years we saw ourselves needing to increase our production again, this time however it was our cheese that was in such high demand. After discussing the project in detail with one of Thermaflo’s process engineers they provided us with a proposal for an HTST pasteuriser capable of processing 12,000L per hour of fresh cheese milk.

Once we had settled on the final design the Thermaflo staff were very quick in completing the fabrication of the pasteuriser and then delivering it to our site. Once all the equipment arrived, Thermaflo staff travelled to Ashgrove to install and integrate the new pasteuriser with the rest of our plant.

Having arrived onsite it only took the Thermaflo staff 8 days to install, commission and train our staff how to operate the new pasteuriser. Whilst they were here, they also took a look at the rest of our plant and carried out work to increase the efficiencies of our entire process.

As Thermaflo have worked on our site before and provided us with equipment in the past we knew they would do a great job and this time round it was no different. I think Thermaflo are a very professional company with great customer service and I would not hesitate to recommend them to others.”